If the goal is a cold, reliable radiator with minimal area, pick a surface that keeps solar absorptance α low and infrared emittance ε high. The sweet spot is α/ε near 0.10. That is why silver shows up everywhere in thermal control stacks, either as silver-coated FEP film, often called Ag/FEP, or as optical solar reflector tiles, OSR, where a thin silver mirror sits behind fused-silica glass.

What to Use, with Numbers

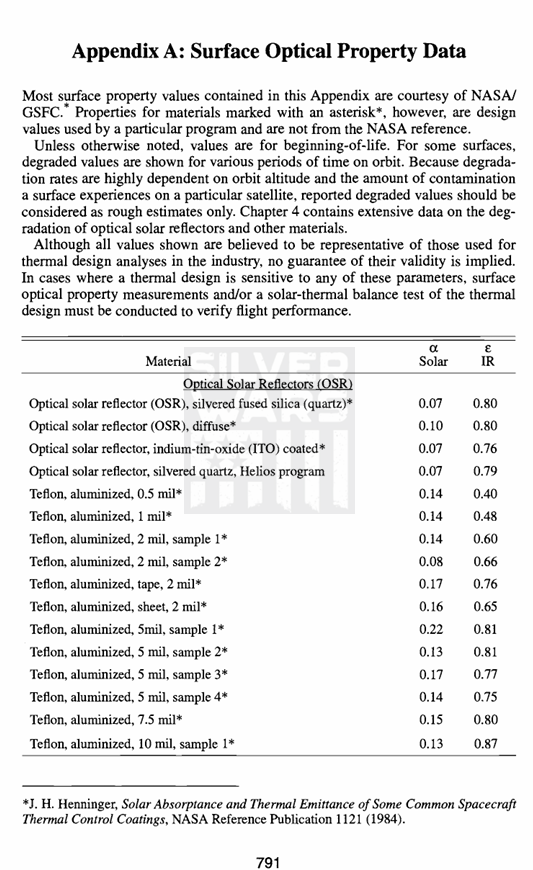

You can size most trades with the values below. These are representative beginning-of-life numbers, always test your actual lot.

| Surface | α | ε | α/ε | Typical use |

|---|---|---|---|---|

| Ag/FEP film, 5–10 mil | 0.08–0.09 | 0.80–0.88 | ~0.10 | Flexible cold-side finish on deployables or panels |

| OSR glass tiles, Ag on fused silica | ~0.07 | ~0.80 | ~0.09 | Rigid, cleanable radiators and doors |

| White paint, Z93 | 0.19–0.23 | 0.88–0.92 | 0.21–0.26 | Low cost, tougher, runs warmer |

| Aluminized polymer, Kapton or FEP | 0.20–0.30 | 0.80–0.90 | 0.22–0.38 | MLI outer covers, not the coldest option |

Plain rule, replacing Z93 with Ag/FEP typically cuts required radiator area by about half for the same sink and load, because α/ε drops from roughly 0.23 to roughly 0.10.

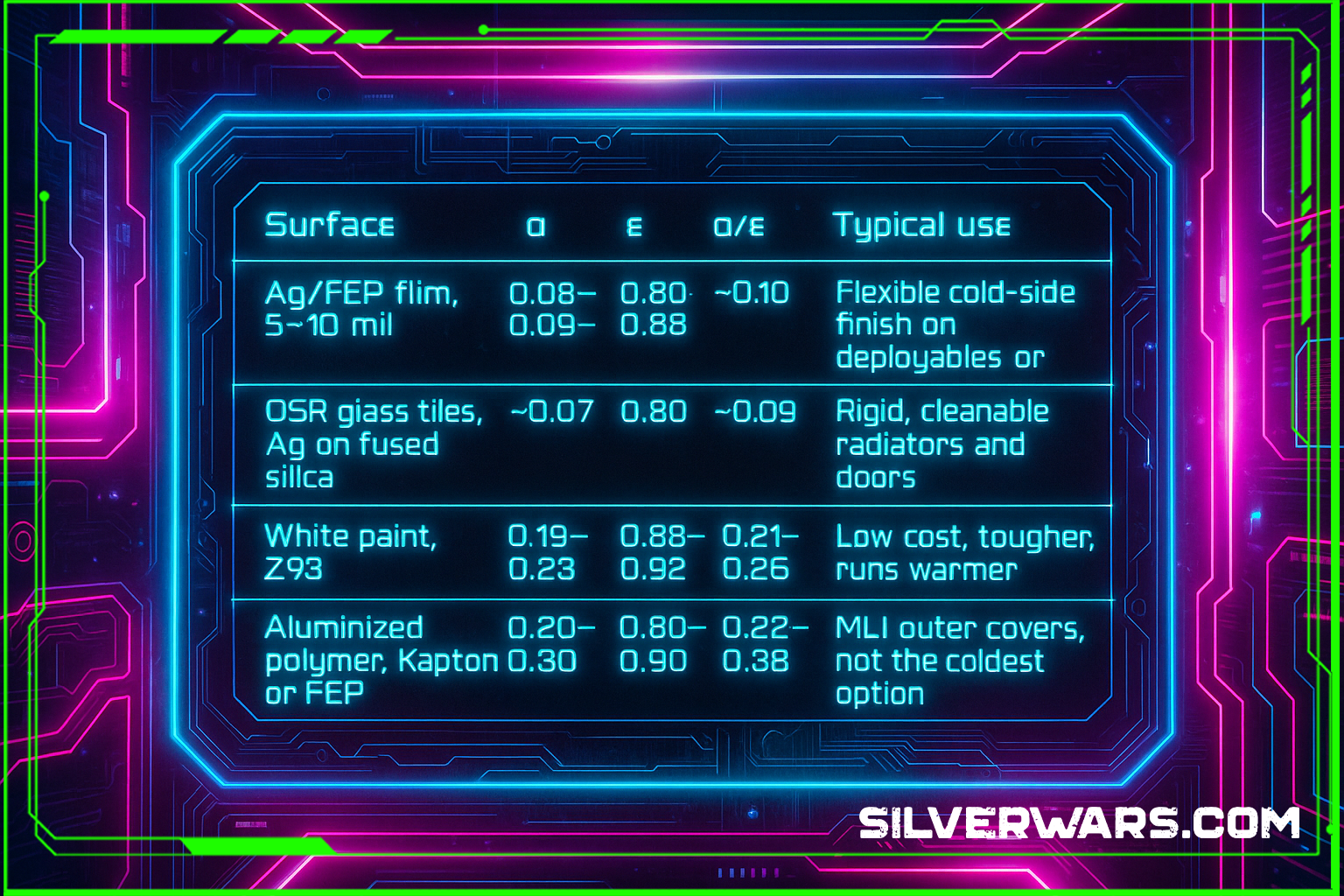

How much silver you actually need

The silver layer is a thin mirror, tens to a few hundred nanometers. Use silver density 10.49 g per cm³ and you get, at 100 nm thickness, about 1.05 g of silver per square meter.

- 50 nm, ~0.52 g per m²

- 100 nm, ~1.05 g per m²

- 200 nm, ~2.10 g per m²

Example, a 10 m² radiator with a 100 nm Ag layer carries roughly 10.5 g of silver. Milligrams of Ag buy you tens of watts of heat-rejection margin when α/ε drops.

Pick quickly, know the trade-offs

- Need the smallest cold radiator, pick Ag/FEP, great α/ε near 0.10, light and flexible. Watch electrostatic discharge, add an ITO bleed layer when needed, manage contamination, consider atomic oxygen protection in LEO.

- Need a rugged panel you can wipe and inspect, pick OSR tiles, similar optics, easy to clean, confirm tile gap losses, handle carefully, accept higher mass.

- Need a budget outer blanket, pick aluminized Kapton or FEP, widely available, ε is fine, α is higher, the radiator will run warmer.

- Need a stray-light absorber, pick black paint like Z306, high α and ε, good for baffles, expect hot hardware, not for cold plates.

The fuse is lit. Will you be ready when silver takes off?

In Silver on the Launch Pad, renowned author James R. Cook teams up with financial insiders to reveal what could be one of the most explosive opportunities in today’s markets—silver.

Degradation in Orbit, Plan to End of Life

Surfaces age. Alpha usually creeps up, epsilon can drift. Budget the increase, qualify your stack.

- Atomic oxygen in LEO, erodes Kapton, roughens FEP, can undercut thin metals at edges, α rises.

- UV plus contamination, outgassing films darken under UV, housekeeping matters or you accept warmer end-of-life optics.

- Thermal cycling, large day-night swings can micro-crack stacks without proper overcoats and primers.

Design to end-of-life α and ε, not just brochure beginning-of-life values.

Worked example, quick back-of-envelope

Load is 40 W, target near 270 K, simple LEO view with margin for Earth IR and albedo.

- With Ag/FEP, α ≈ 0.08, ε ≈ 0.82, area lands around 0.4 to 0.6 m² at beginning of life.

- With Z93, same target and load, expect roughly 0.8 to 1.0 m².

- Silver mass check at 0.5 m² and 100 nm, about 0.5 g of Ag.

Silver Wars is dedicated to Safe Guarding the World's Silver Future.

Handy Material Constants for Calcs

Use these for quick thermal sizing, refine with vendor data at your temperature.

- Silver, k ~419 to 430 W per m·K, cₚ ~235 to 260 J per kg·K, density 10.49 g per cm³

- Aluminum, k ~205 W per m·K, cₚ ~900 J per kg·K, density 2.70 g per cm³

- FEP, k ~0.20 W per m·K, cₚ ~1170 J per kg·K, density 2.12 to 2.17 g per cm³

- Kapton HN, k ~0.12 to 0.20 W per m·K, cₚ ~1090 J per kg·K, density 1.42 g per cm³

Do you want to advertise with Silver Wars? Get in Touch!

The Silver Wars Require More

Aim for α/ε near 0.10, that is the cheat code for cool hardware. Ag/FEP and OSR give you that, with grams of silver across entire radiators. Lock the coating stack early, line up two vendors, test your lot at relevant temperatures and fluence.

| Item | Pg | α (solar) | ε (IR) | α/ε | Notes |

|---|---|---|---|---|---|

| Optical solar reflector (OSR), silvered fused silica (quartz) | 1 | 0.07 | 0.80 | 0.09 | Design value, second-surface mirror (OSR) |

| Optical solar reflector, silvered quartz, Helios program | 1 | 0.07 | 0.79 | 0.09 | Helios reference, second-surface mirror (OSR) |

| Teflon, silvered, 2 mil | 2 | 0.08 | 0.68 | 0.12 | Design value |

| Teflon, silvered, 5 mil | 2 | 0.08 | 0.80 | 0.10 | — |

| Teflon, silvered, 10 mil | 2 | 0.09 | 0.88 | 0.10 | Design value |

| Kapton, silvered, aluminum-oxide coated, 1 mil | 4 | 0.08 | 0.19 | 0.42 | Al₂O₃ protective coat |

| Kapton, silvered, aluminum-oxide coated, 1 mil, 2400 hours UV | 4 | 0.08 | 0.21 | 0.38 | 2,400 h UV exposure, Al₂O₃ coat |

| Chromeric 586 silver paint | 7 | 0.30 | 0.30 | 1.00 | — |

| DuPont 4817 silver paint | 7 | 0.43 | 0.49 | 0.88 | — |

| Silver, vapor-deposited, on glass, un-oxidized | 8 | 0.04 | 0.02 | 2.00 | — |

| Silver, polished, un-oxidized | 8 | 0.04 | 0.02 | 2.00 | Design value |

| Silver, oxidized | 8 | — | 0.03 | — | Design value, α not given |

| Silver, Denton vapor-deposited, with protective overcoat | 8 | 0.06 | 0.03 | 2.00 | Design value |

| Silver beryllium copper | 8 | 0.19 | 0.03 | 6.33 | — |

| Silver beryllium copper with Kapton overcoat | 10 | 0.31 | 0.57 | 0.54 | Kapton overcoat |

| Silver beryllium copper with Parylene C overcoat | 10 | 0.22 | 0.34 | 0.65 | Parylene C overcoat |

| Silver beryllium copper with Teflon overcoat | 11 | 0.12 | 0.38 | 0.32 | Teflon overcoat |