The Strategic Use of Silver Plating in Military Finishes: A MIL-DTL-14072G Breakdown

When it comes to military-grade finishes for ground-based electronic equipment, precision and performance are paramount. The Department of Defense detail specification, MIL-DTL-14072G, outlines the exacting requirements for protective coatings. While many industrial coatings use "silver" to describe a color, this specification details applications where actual silver metal is required for its unique engineering properties. Let's explore the specific instances where real silver plating is mandated.

The Research we do is made possible by our sponsor Investment Rarities and Public Donations. Thank You For Your Support!

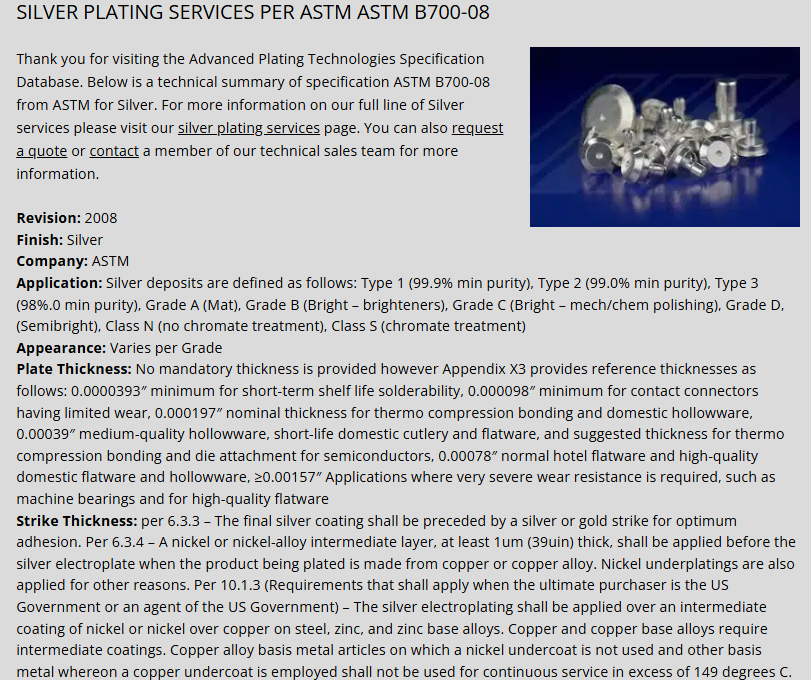

1. The Engineering Standard: ASTM B700

The military specification explicitly incorporates ASTM B700, the "Standard Specification for Electrodeposited Coatings of Silver for Engineering Use". This citation confirms that the document's references to silver plating are not about aesthetics but about applying a functional layer of actual silver metal for specific performance characteristics like conductivity and corrosion resistance.

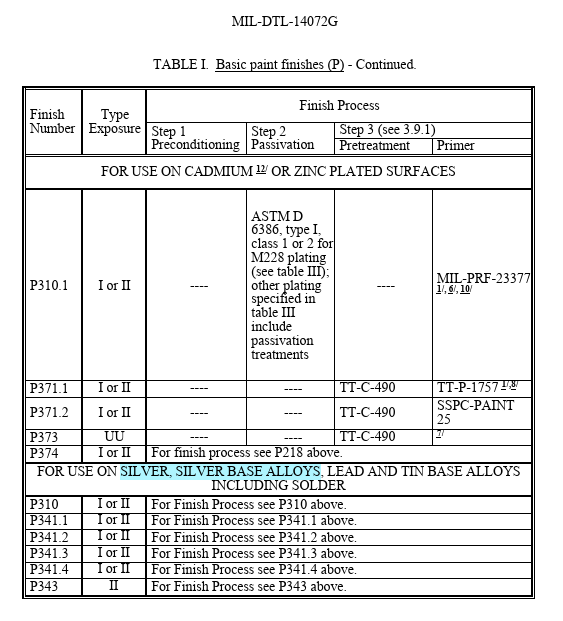

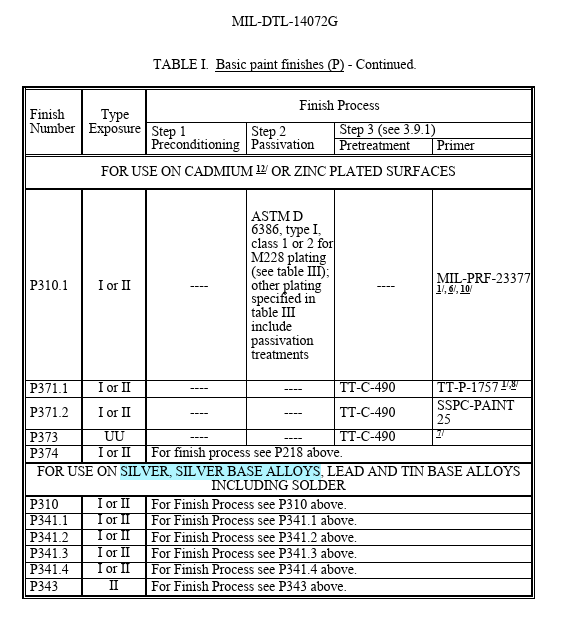

2. Finishes for Silver Base Alloys

The specification provides guidance for applying paint finishes not just with silver, but also onto it. Table I includes a dedicated section for "USE ON SILVER, SILVER BASE ALLOYS...". This acknowledges that components made from silver or its alloys may be used in military electronics and require their own specific surface treatment protocols.

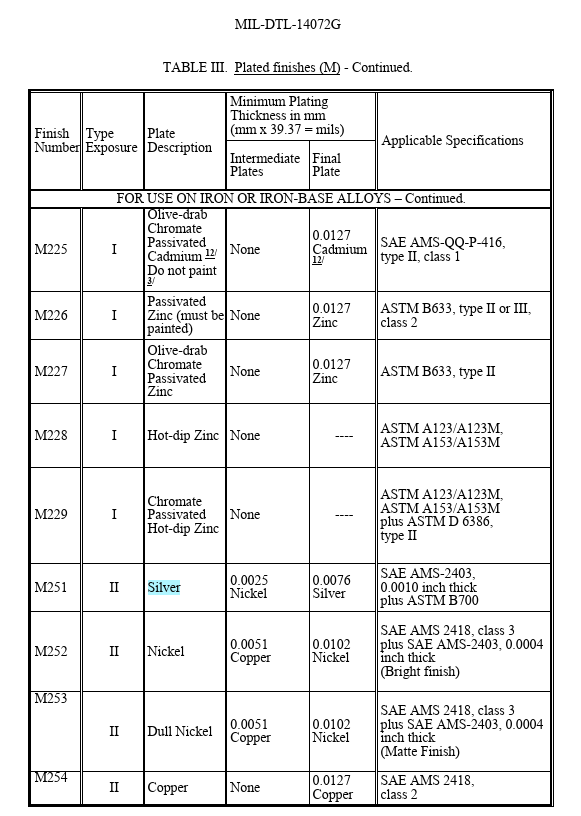

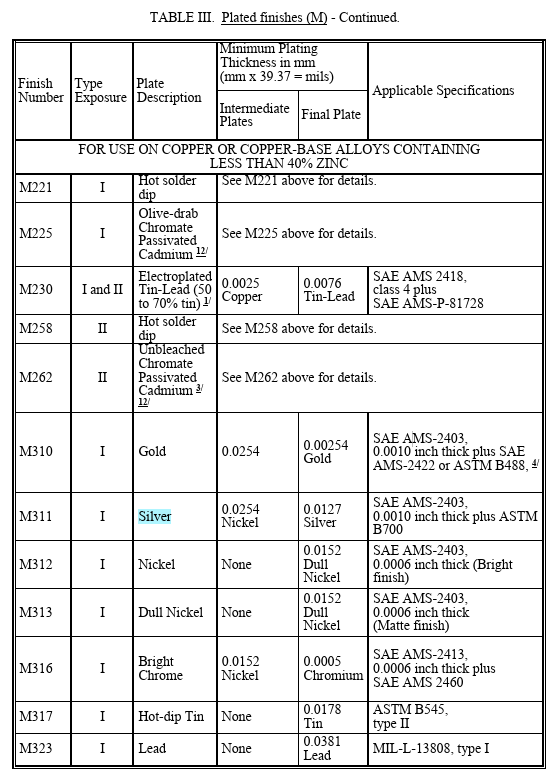

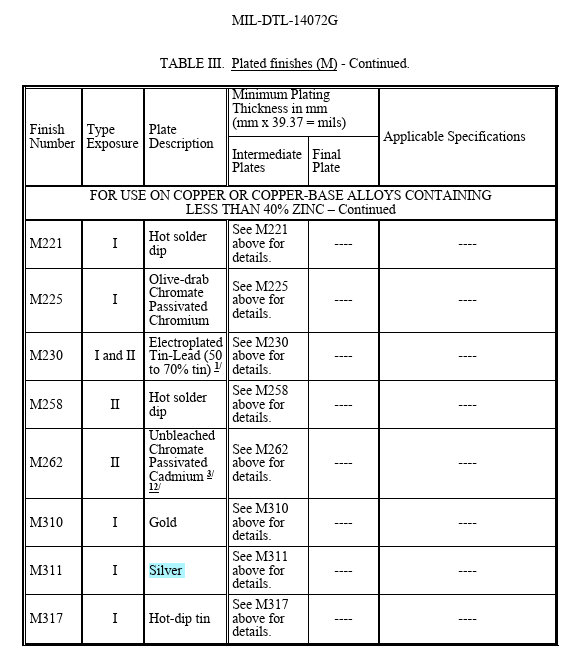

3. Designated Silver Plating Finishes (M-Series)

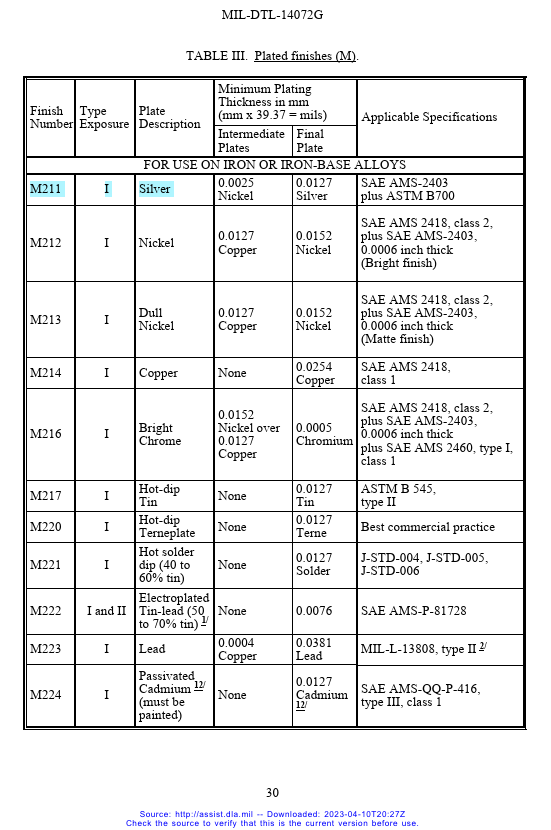

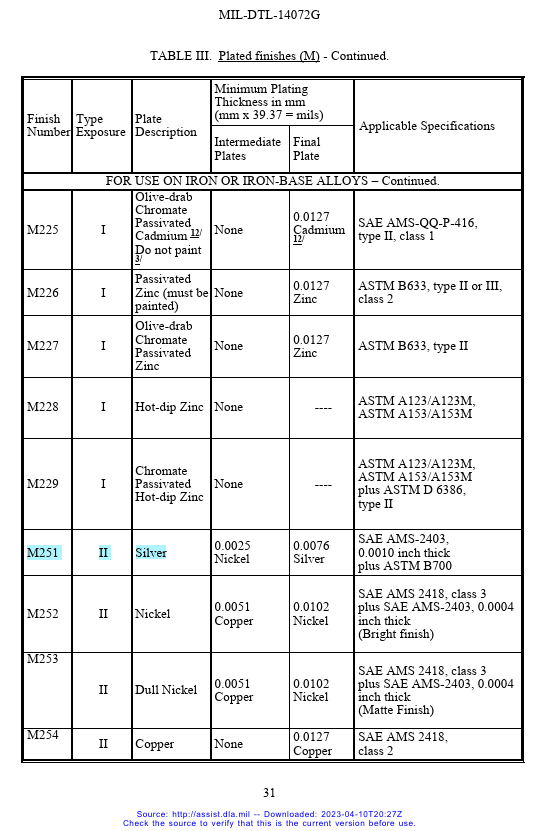

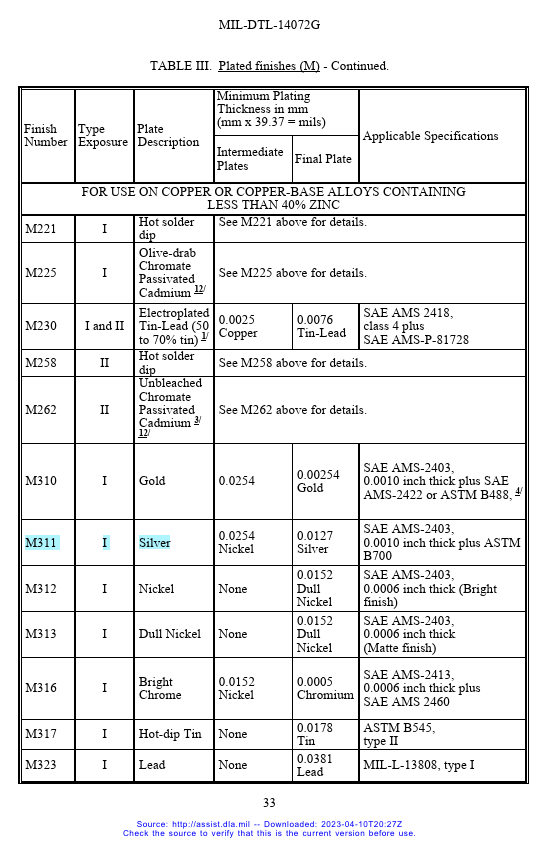

Table III of the document, "Plated finishes (M)," lists specific codes for when silver plating must be used. These finishes are designated for different base metals and exposure conditions.

- Finish M211: This calls for silver plating over a nickel undercoat on iron or iron-base alloys intended for high-exposure (Type I) environments.

- Finish M251: This designates a silver plate over a nickel undercoat for iron and its alloys in more sheltered (Type II) applications.

- Finish M311: For copper and copper-base alloys, this finish requires a silver plate with a minimum thickness of 0.0127 mm over a nickel undercoat.

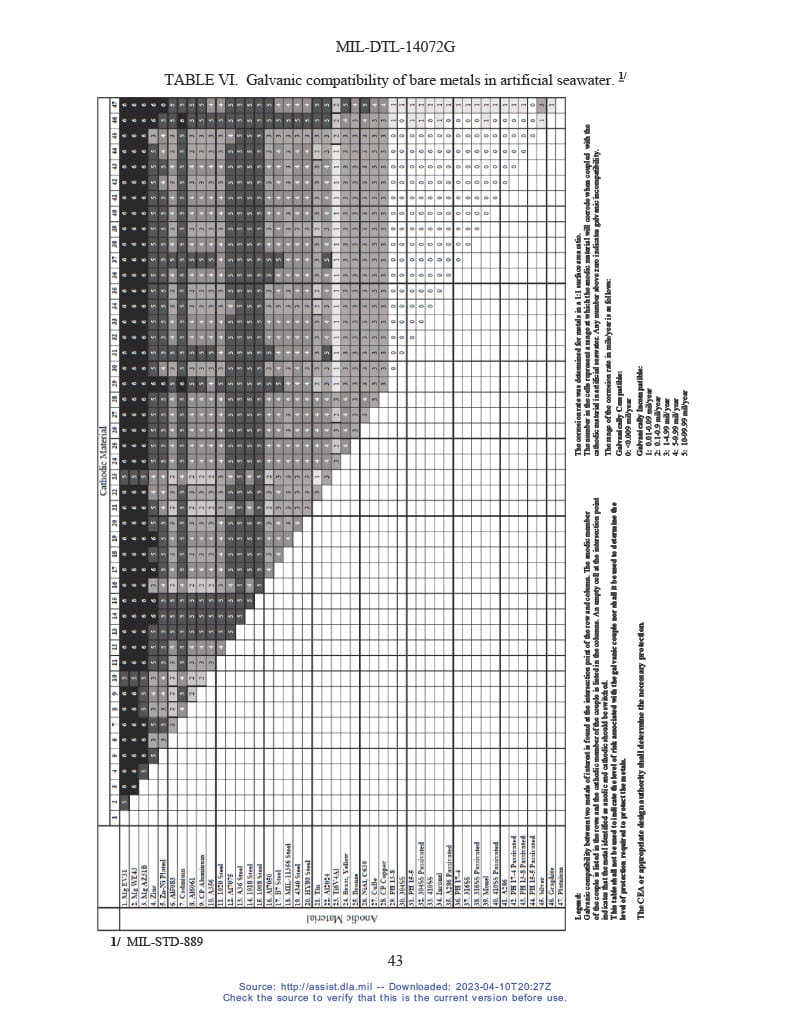

4. Silver's Role in Galvanic Compatibility

Preventing corrosion from dissimilar metal contact is a critical design consideration. Table VI, the "Galvanic compatibility of bare metals" chart, lists "Silver" as a distinct material (No. 45). Its position in this electromotive series is crucial for engineers to determine the potential for galvanic corrosion when silver-plated parts are in contact with other metals, ensuring the long-term reliability of the electronic equipment.