I’m going to make this simple: if you want a cold, reliable spacecraft radiator, you pick a surface with a tiny alpha/epsilon (α/ε) ratio, and nine times out of ten that means silver somewhere in the stack—usually silver‑coated FEP (Ag/FEP) or optical solar reflector (OSR) glass tiles. Below is a stripped‑down, plain‑English guide with the numbers you’ll actually plug into a quick trade, plus how much silver that really uses.

What matters most (α/ε, in one minute)

Think of α as “how much Sun you soak up” and ε as “how easily you glow heat back out.” You want low α, high ε. That ratio α/ε ≈ 0.1 is the cheat code for cool hardware. Silver is great at reflecting visible/near‑IR (low α), while FEP Teflon on top stays IR‑emissive (high ε). This is why Ag/FEP keeps showing up in thermal control handbooks.

Plain rule: if you replace white paint (α/ε ~0.25) with Ag/FEP (α/ε ~0.10), the same Sun leads to a much cooler equilibrium temperature, or—equivalently—you can shrink the radiator area.

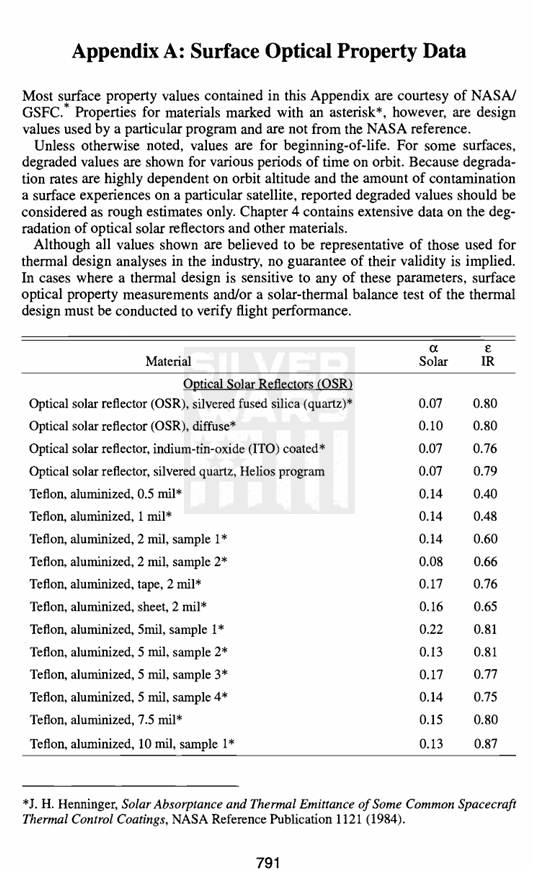

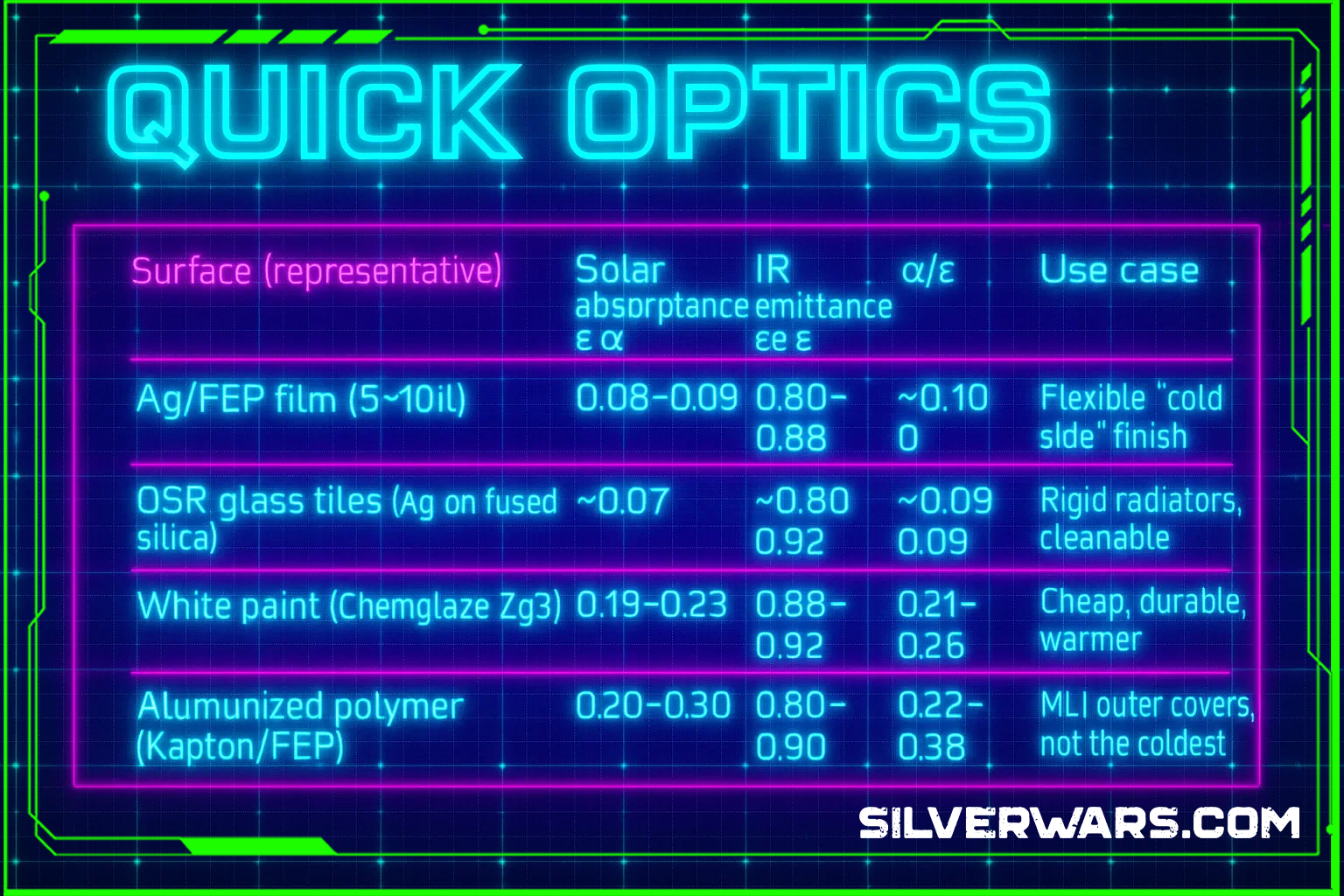

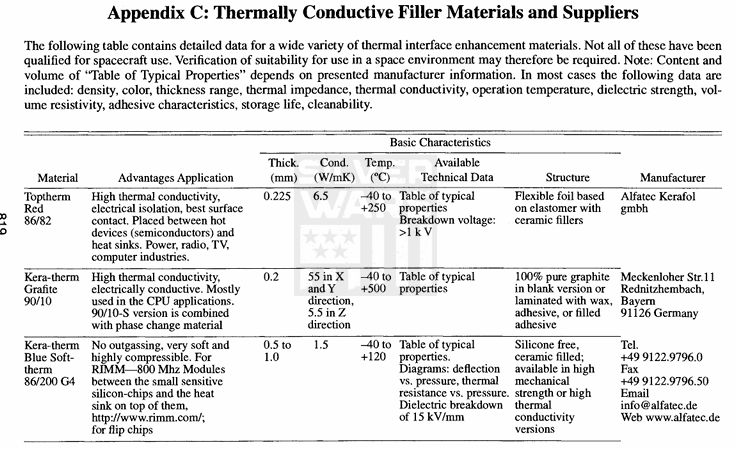

Quick optics at beginning‑of‑life (BOL)

| Surface (representative) | Solar absorptance α | IR emittance ε | α/ε | Use case |

|---|---|---|---|---|

| Ag/FEP film (5–10 mil) | 0.08–0.09 | 0.80–0.88 | ~0.10 | Flexible “cold side” finish |

| OSR glass tiles (Ag on fused silica) | ~0.07 | ~0.80 | ~0.09 | Rigid radiators, cleanable |

| White paint (Chemglaze Z93) | 0.19–0.23 | 0.88–0.92 | 0.21–0.26 | Cheap, durable, warmer |

| Aluminized polymer (Kapton/FEP) | 0.20–0.30 | 0.80–0.90 | 0.22–0.38 | MLI outer covers, not the coldest |

| These are typical measured values; always test your actual lot. |

The fuse is lit. Will you be ready when silver takes off?

In Silver on the Launch Pad, renowned author James R. Cook teams up with financial insiders to reveal what could be one of the most explosive opportunities in today’s markets—silver.

How The Silver is Used

The reflective Ag layer in Ag/FEP or OSR is nanometers thin—think ~20–200 nm. Convert that to mass using silver’s density (10.49 g/cm³) and you get about 1 g of Ag per square meter at 100 nm. A “big” 10 m² radiator? Roughly 10 g of silver.

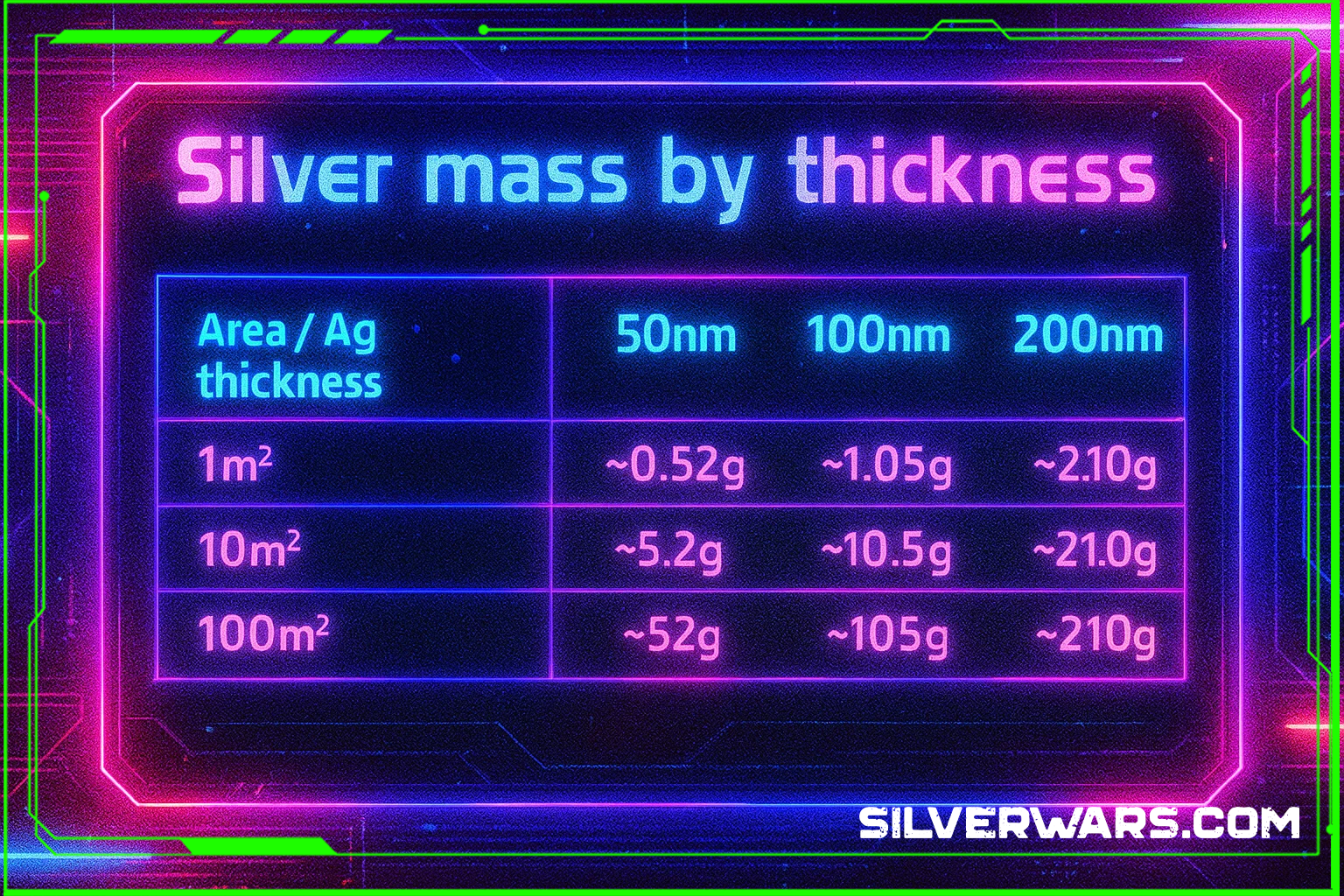

Silver mass by thickness

| Area / Ag thickness | 50 nm | 100 nm | 200 nm |

| 1 m² | ~0.52 g | ~1.05 g | ~2.10 g |

| 10 m² | ~5.2 g | ~10.5 g | ~21.0 g |

| 100 m² | ~52 g | ~105 g | ~210 g |

| That’s the leverage story: milligrams of silver buy you tens of watts of heat‑rejection margin when α/ε drops. |

Silver Wars is dedicated to Safe Guarding the World's Silver Future.

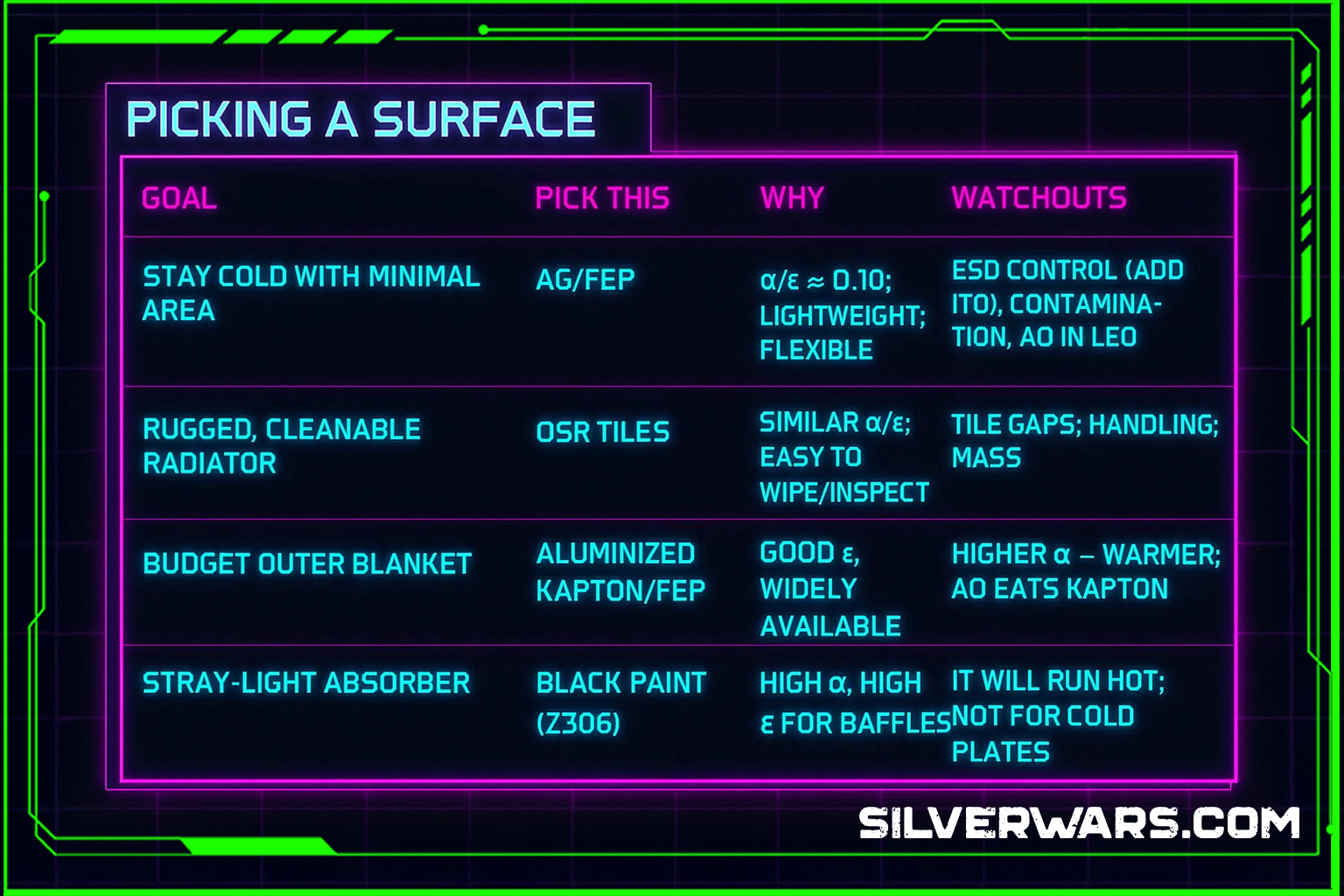

Picking a Surface

| Goal | Pick this | Why | Watch‑outs |

| Stay cold with minimal area | Ag/FEP | α/ε ≈ 0.10; lightweight; flexible | ESD control (add ITO), contamination, AO in LEO |

| Rugged, cleanable radiator | OSR tiles | Similar α/ε; easy to wipe/inspect | Tile gaps; handling; mass |

| Budget outer blanket | Aluminized Kapton/FEP | Good ε, widely available | Higher α → warmer; AO eats Kapton |

| Stray‑light absorber | Black paint (Z306) | High α, high ε for baffles | It will run hot; not for cold plates |

| These are the default choices you’ll see in heritage spacecraft. |

Do you want to advertise with Silver Wars? Get in Touch!

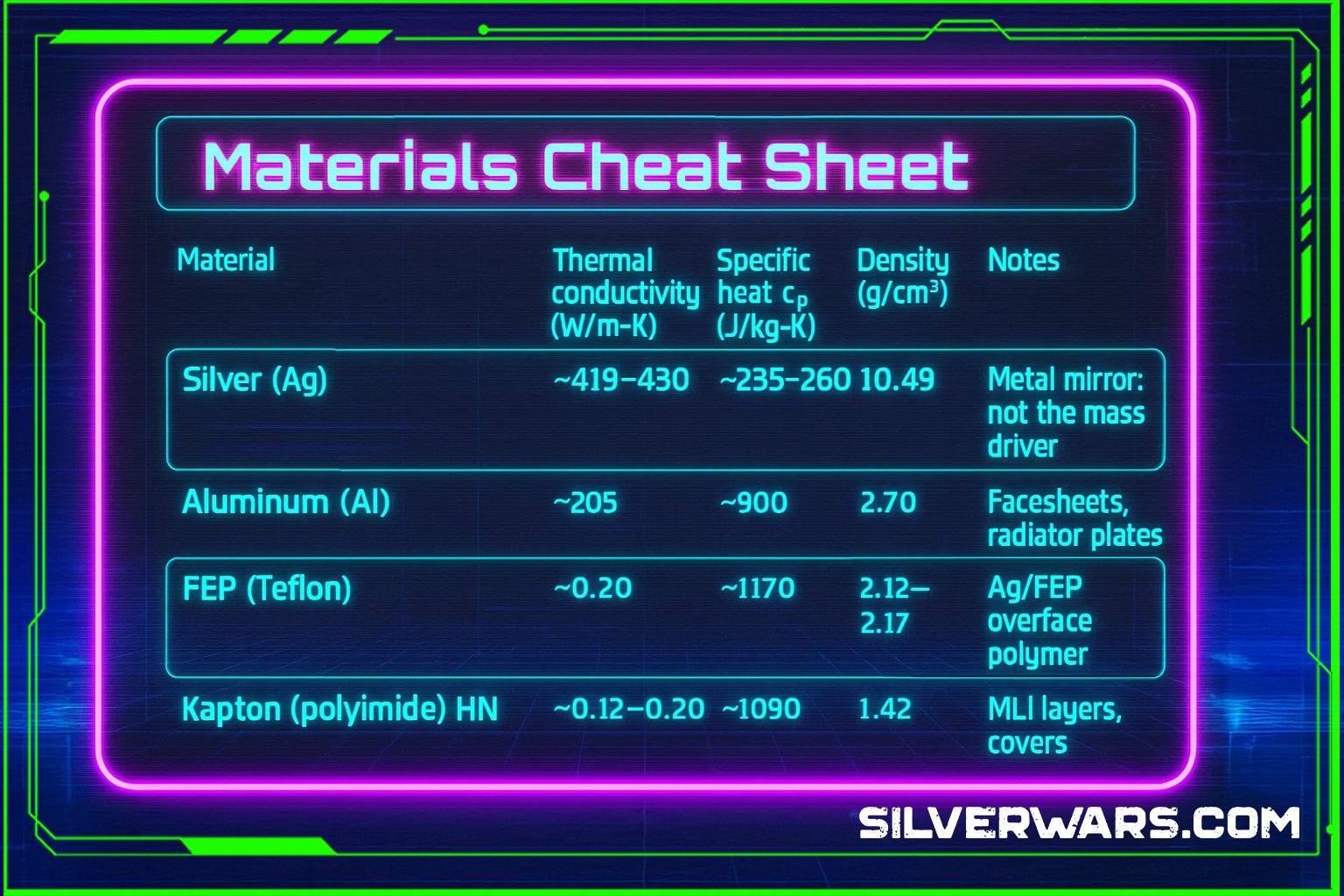

Materials Cheat Sheet

| Material | Thermal conductivity k (W/m·K) | Specific heat cₚ (J/kg·K) | Density (g/cm³) | Notes |

| Silver (Ag) | ~419–430 | ~235–260 | 10.49 | Metal mirror; not the mass driver |

| Aluminum (Al) | ~205 | ~900 | 2.70 | Facesheets, radiator plates |

| FEP (Teflon) | ~0.20 | ~1170 | 2.12–2.17 | Ag/FEP overface polymer |

| Kapton (polyimide) HN | ~0.12–0.20 | ~1090 | 1.42 | MLI layers, covers |

| If you need exact numbers, pull the vendor data for your lot and temperature. |

Wall Street Silver Reddit is the Home of #SilverSqueeze. We love silver. Every Troy Ounce! No diamond-hands without EXTREME Pressure!

[Now Under SILVER WARS Management]

Degradation (BOL → EOL) without the jargon

Surfaces age in orbit. Expect α to creep up (warmer) and sometimes ε to drift. Budget for it up front.

- Atomic oxygen (LEO): Erodes Kapton, roughens FEP, can undercut edges of thin metals. Result: α goes up.

- UV + contamination: Outgassing films darken under UV. Keep things clean or accept warmer EOL.

- Thermal cycling: Big eclipse swings can micro‑crack layers if the stack isn’t well protected. Put simply: design to EOL α/ε, not just BOL brochure numbers.

Worked Example (step‑by‑step, no heavy math)

Problem: Your payload dumps 40 W and needs to sit around 270 K (‑3 °C). What radiator area gets you there in LEO?

- Pick a surface: Start with Ag/FEP (α ≈ 0.08, ε ≈ 0.82).

- Assume a simple view: Radiator sees deep space mostly; allow some Earth IR/albedo in your margin.

- Use the radiative balance idea: Emitted power ≈ εσT⁴ × area. Lower α also keeps Sun gain small.

- Back‑of‑envelope result: You’ll land around ~0.4–0.6 m² at BOL with Ag/FEP. Switch to white paint and you typically need ~0.8–1.0 m² for the same temperature.

- Silver mass check: At 0.5 m² and 100 nm Ag, you’re carrying ~0.5 g of silver. Double thickness? Still ~1 g.

That’s the headline: grams of silver can save half the radiator area.

Why “grams of silver” Still Matter in Programs

By mass, space doesn’t use much silver. But by mission criticality, those grams are non‑negotiable. Coating delays or supply hiccups can slip an entire thermal schedule even though the BOM only calls for a teaspoon of Ag. Plan dual sources and lock the stack early.

The Silver Wars Continue...

Choose a silver finish (Ag/FEP or OSR), design for end‑of‑life numbers, and line up the tiny but critical silver parts early. Do those three things and your spacecraft runs cooler, your radiator is smaller, and your schedule stays on track.

So, you better get your silver now if you want anything going up in space.